In the latest episode of The Siliconist podcast, host John Cole engages in a fun discussion with Mitchell Hsing, co-founder and CEO of InchFab.

You too can own a fab in your backyard, for just a few million USD . . . we’ll talk about why you should get one.

Understanding Microfabrication

Microfabrication is an intricate process that allows for the manufacturing of devices and materials at a microscopic scale. Inch Fab is pioneering this field by providing application-specific fabs that drastically reduce the cost and footprint required for traditional fabrication methods. According to Mitchell, their entire fab line occupies just about 100 square meters and costs between $5 to $10 million. This is a significant reduction compared to the billions often required for larger fabs.

The Origin of Inch Fab

In a world of mega fabs, gigafabs, and terrafabs, why’d Mitchell go small? The company's inception traces back to the PhD research conducted by Mitchell and his co-founder at MIT, where the objective was to democratize the fabrication process. They aimed to lower the barriers to entry, enabling more innovators to create at the micro scale.

As Mitchell recalls, their early equipment was often outdated, sometimes requiring the use of floppy disks, showcasing how innovation can thrive even with limited resources.

A Shift in Business Model

We discuss how Inch Fab has shifted its business model from providing foundry services to offering manufacturing lines. This strategic pivot responds to a growing global demand for decentralized fabrication solutions. As industries increasingly seek flexibility and cost-effectiveness, Inch Fab’s model proves timely and necessary.

Democratizing Fabrication

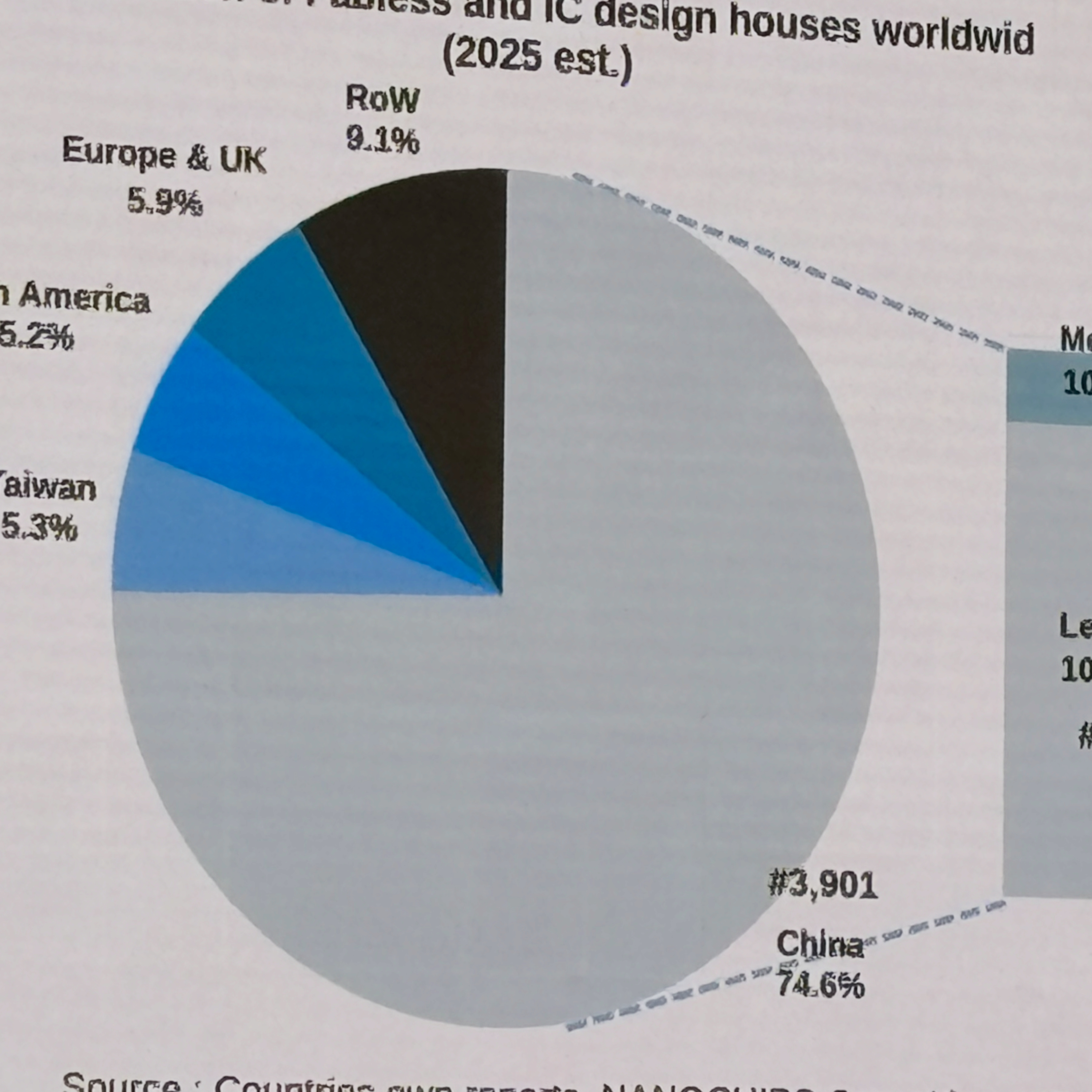

Inch Fab's mission is not purely educational; rather, it aims to empower individuals and smaller companies that may not have the resources to engage with larger semiconductor fabs. Mitchell emphasizes that approximately 80% of current products do not justify the economics of a multi-billion dollar fab, indicating a vast market potential for smaller-scale fabrication. This approach opens the door for innovation across various sectors that previously struggled with high entry costs.

The Future of Microfabrication

Finally, we take some time to discuss emerging trends in semiconductor manufacturing, including the shift towards application-specific designs. The barriers of traditional fabrication are being challenged as new material stacks and innovative designs take center stage. Mitchell notes that the future will likely see more diverse applications and the rise of technologies such as quantum computing and diamond-based electronics.